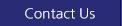

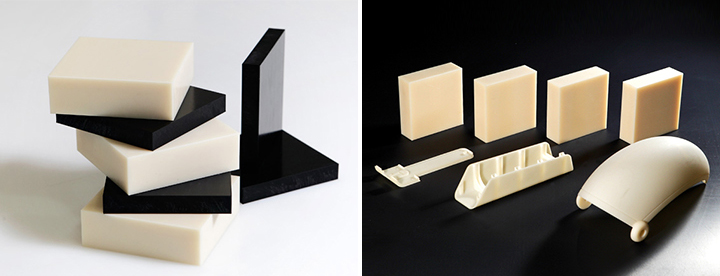

| ABS ( Acrylonitrile Butadiene Styrene ) |

Today, ABS has widely been used as thermo engineering plastic in various industries and such ABS is produced through compounding with bleding of thermo rubber, styrene and acrylonitrile polymers. The combination of such co-polymers gives the excellent characteristics such as scratch resistance, glossy textured surface. ABS plastic do not only exhibit better impact strength and stiffness than HIPS( high impact polystyrene ) but also superior chemical properties such as higher heat resistance, chemical resistance. Thereby, ABS has been taken center stage as important material in many fields. SP Polymer ABS sheets and Rod are not only easily machinable with high speed carbide tool in NC milling, Die-cutting, Routing, Drilling but also give easy mechanical finishes such as Filling, Grinding, Sanding, Buffing and Polishing. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||